Summary

I am a professional with the engineering background and having diversified experience in operations and supply chain management. Having a track record of designing and implementation of engineering tools, applying cost reduction and supply chain management with the essentials of quality and safety on production & manufacturing organizations. Nowadays looking for a position in the reputed company like you to pursue my career, while maintaining your strategy and want to be a part of your growth.

Projects

Experience

Deputy Manager Operations

– Planning: Led strategic sourcing and procurement initiatives for 3-ton/day raw materials, ensuring timely and cost-effective acquisition while adapting to demand fluctuations.

– Communication: Proactively communicated with departments across the organization to identify procurement needs and ensure supply chain continuity.

– Project management: Managed around 21, Six Sigma projects from start to finish, overseeing troubleshooting and scheduled maintenance to ensure optimal production.

– Negotiation: Collaborated with vendors to negotiate and secure raw material delivery at optimal prices, fostering positive stakeholder relationships.

– Enterprise Resource Planning: Lead and Manage the organizational resources for efficient business

activities with system-generated reports and data analysis for better integration of all the departments.

– Technology upgradation: Accomplished the planning and implementation of an ERP system, resulting in streamlined business operations and increased efficiency.

– De-bottlenecking: Implemented de-bottlenecking measures, such as eliminating redundant processes and improving material flow, resulting in 16% enhanced production, 24% increased efficiency, and 19% reduced downtime.

Assistant Manager Operations

– Supply Chain Management: Regulated all the departments to build an effective supply chain, which outperformed with 22% of the overall profit to the organization.

– Planning: Organizing all the operations of smooth supply; from raw material to final product’s delivery to consumers, by aligning all departments of the organization.

– Inventory Management: Reduced the warehousing cost by 15% with my inventory management skills.

– Production Process: Integrated all the production lines of 75 Ton/day fruit pulp to achieve smooth results and make the production process easy to handle and achieve BRC “level A” in Quality Management Audit.

– Negotiation: Overseeing the procurement process and negotiating the price to reduce the cost of raw materials so that after value addition final product should be in the range of maximum consumers.

– Troubleshooting: Reconciling all the departments on the bases of SOPs to run the operations smoothly.

– Report writing: Simplified the reporting system of the organization to make that effective for BRC auditing.

– Route Planning/ Scheduling: Perform metrics reporting and data analysis tasks to identify low-cost logistics routes and opportunities for process improvements with minimum lead time.

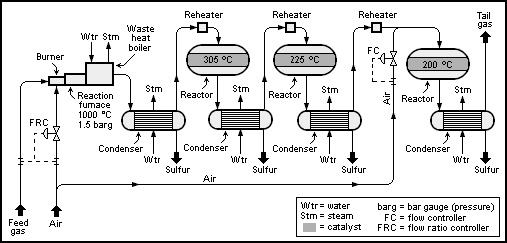

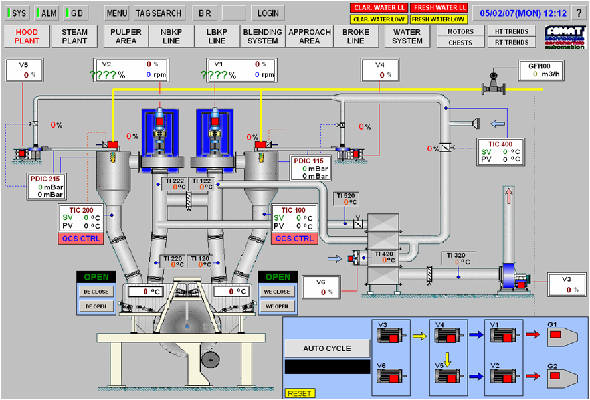

Production\Process Engineer

– Production: Shaped the production of 120-ton paper/ day with ISO 9001 and ISO 14001, to reduce the environmental impact of the manufacturing process.

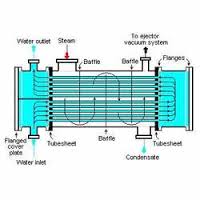

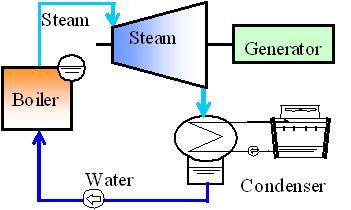

– Designing: Designed and executed the insulation of 1800-meter steam lines along with a preheating system for the raw material to minimize the 16% steam consumption.

– Troubleshooting: Investigated the regular troubleshoots and established the maintenance schedule to run the daily production process trouble-free.

– Unit operations: Checked all the unit operations; Fluid Mechanics, Heat Transfer, Extraction, Evaporation, and De-humidification, going on in papermaking.

– Project Management: Facilitated project management in the erection of a new production line of 80 Ton per day.

– Auditing: Performed monthly reviews of all the operations to gain a production cost reduction of 16% and process optimization of 28%.

– Cost optimization: Established a recycling system to reduce the cost of raw material by 8% and the 7% gain in the value of waste.